How to ensure even coating effect? Here is the solution!

There was such kind of oil-paper umbrella which could keep rain off yet not broken in ancient China. It is known to all that paper is too fragile to endure water. How did ancient people get over with this problem? It is vital to find In the last process of making umbrella, what matters is to apply boiled tung oil uniformly on its surface as its coating.

Nowadays coating material has been widely used in daily life. Differed from ancient method, coating machine is more used to make some special materials, in order to achieve some special needs or enhance the protective effect of material.

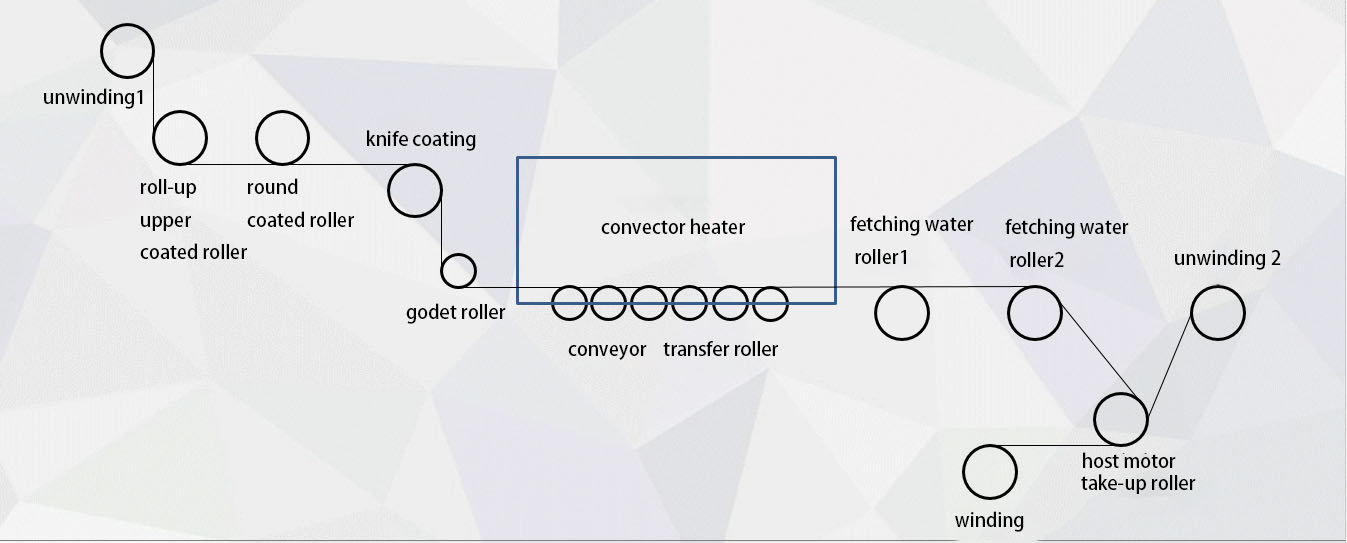

Coating machine is used to evenly coat the material with glue, paint, or ink, and then wind the materials after drying out. The material usually covers paper, cloth, leather, aluminum foil, plastic film, etc.

In the entire process, coating link is so important that directly determines the quality of the production material.

Just like the base makeup, skin color will be uneven if the liquid foundation is not evenly coated. If the material is not evenly coated, it will be hard to guarantee the same protective effect per square of the material, which will cause economic losses.

Therefore, in order to ensure production efficiency and quality, the control system of coating machine should realize constant tension and high-speed automatic roll change without stopping.

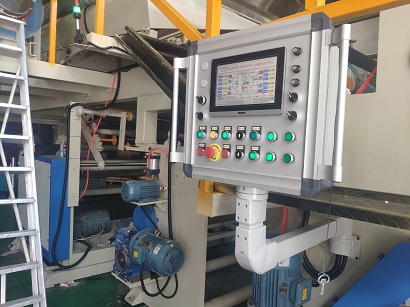

Hpmont coating machine control system

Winding mechanism adopts torque control without tension feedback. Material feeding speed is controlled by closed loop. Double stations automatic feed material and change coil, which can avoid bad cabbage type winding.

System benefits:

■ HC10 series IPLC can achieve tension control and other complex logic functions based on excellent algorithm, and it also supports a variety of extension modules.

■ HD50 high performance inverter has functions of linear speed control adjustment, length control and shutdown, etc. A large number of virtual terminals are available, which can provide three-station unwinding and double-station winding control. At the same time, it also has the function of winding and unwinding tension control, which can be flexibly switched smoothly through external terminals.

■ The HD50-A2 inverter can realize the position control of pulse train, ensuring the real-time synchronization of the glue inverter and the traction motor, and easy adjustment.

■ Functional process card can realize secondary development by programming based on the field process. It can be inserted in the inverter, saving more space.

■ Ventilation system is interlocked with control system to ensure production safety.

Application case:

Large high-end coating machine: four-station unwinding and double-station winding, aluminized film

Electrical configuration:

2 10-inch HV01 series touch screen

3 HC10 series IPLC main modules, CAN communication between modules

64 input channel, 48 output channel, 8 high-speed pulses, 15 analog channels

15 ventilators are controlled by HD20 inverter

12 motors of winding and unwinding are controlled by HD50 inverters

There are three kinds of gluing modes for choice: mesh coating, transfer coating, and scratch coating. The operator could select a certain part of the machine to glue by HMI so that the other gluing parts can run without linkage, thus avoiding resource loss.

Double-station unwinding has tension feedback speed control. Winding has two control modes including with torque control without tension feedback and speed control with tension feedback. The middle drive mechanism with tension pendulum rod adopts PID synchronous control, ensuring even coating.

With high compatibility and powerful functions, this whole control system has been widely applied in high-end coater, helping countless users to greatly improve the stability of machine system and enhances production efficiency.

Continuous research on technology innovation and consideration of user needs are the key to success in the market. Hpmont is working on industrial automation industry to provide more efficient and high-end solutions for customers.