How to choose a high-power inverter befitting mine equipment?

The process of mining is extremely complex, including exploration, crushing, grinding, dressing, smelting, refining and so on. Common equipment are water pumps, mine ventilators, mine elevators, crushers, ball mills, mineral processing equipment and smelting equipment.

The equipment and labor force has already occupied a large amount of cost for owner of mine. How can we reduce mining costs as much as possible in other aspects? It is vital to choose an energy-saving inverter.

What you should give priority to is its heat dissipation performance, power grid adaptability, harsh environment adaptability, system stability and reliability.

Hpmont inverters could perfect meet the above requirements.

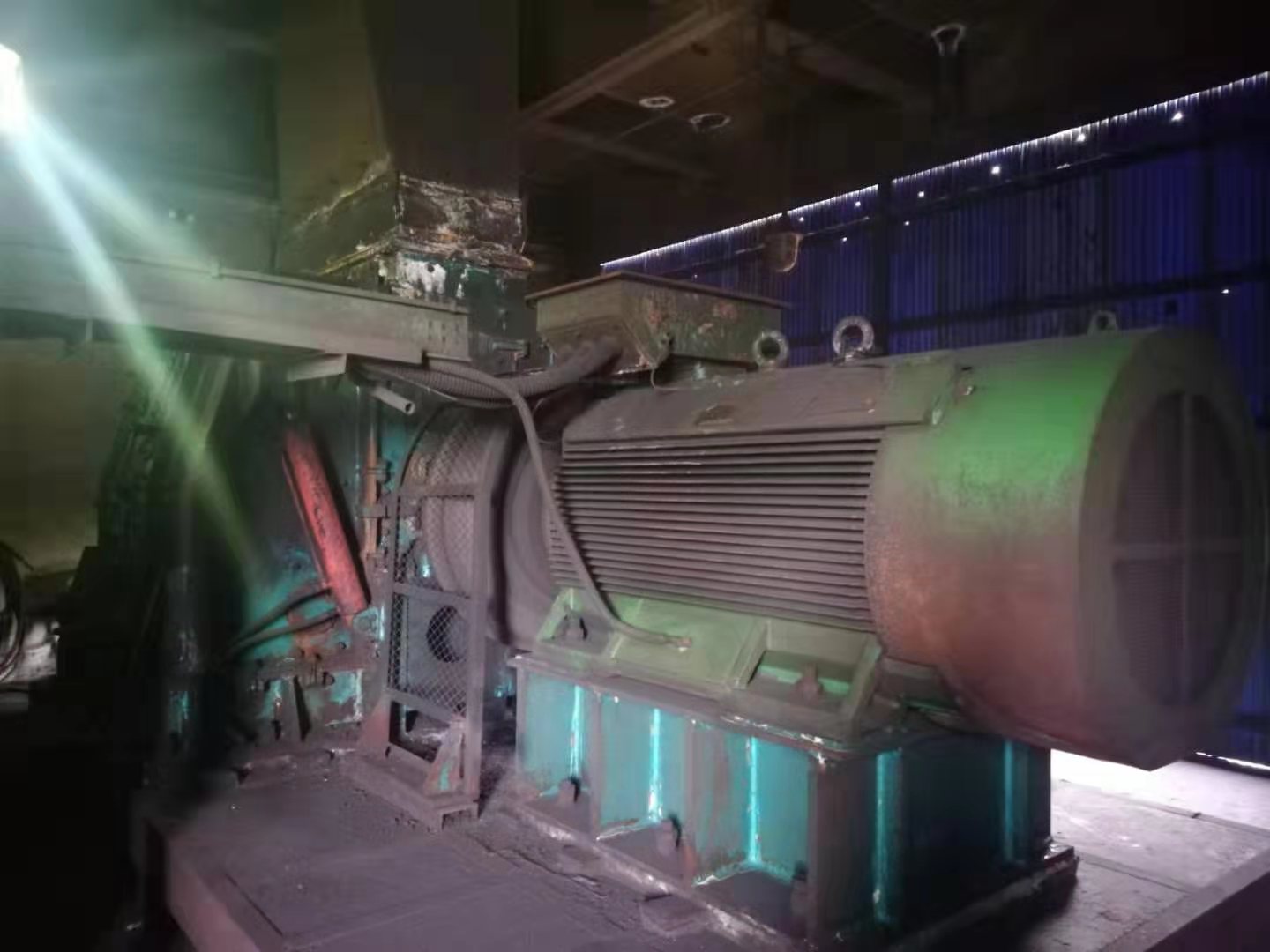

Recently, Hpmont HD30 vector control inverter of 630kw was applied in coal crushers in a coking plant, Shandong.

Based on the advanced technology of open-loop torque vector control, HD30 inverter is able to output sufficient torque at low-frequency startup.

In the mine lifting site of a copper mine in Yunnan Province, the inverter power was 315kw. The function of low frequency but large torque fully decreased the energy waste and improved system stability.

At the same time, it is also in line with the control requirements of ball mill.

It often needs 24-hour uninterrupted operation for ball mill to grind large particles of ore into powder. Moreover, the machine is possible to operate continuously for several months once starting. Therefore, it is particularly significant to ensure that the ball mill can work continuously at large load.

Ball mill, Suichuan - 315 kw

The wide voltage design of AC200~460V ensures the high adaptability of power grid, minimizing the impact of voltage fluctuations on the equipment.

Ball mill, Shanxi - 315 kw

Vertical mixing ball mill- 400 kw / 355kw

Ore mining and processing environment is harsh, with moisture, high temperature, dust, and mud during the whole process. Don’t worry. By using the latest IGBT modules, independent cooling duct design, and PCB board sprayed with three times thicker of three-proofing insulating paint than the typical one, Hpmont products show higher resistance to harsh environments.

Mining pump, Eshan- 6 units of 220 kw inverters

In the ore smelting stage, mine ventilators are often used for heat dissipation. Although it is a typical light-load equipment, its large inertia also troubles users. The shutdown process of equipment often lasts more than ten minutes, or even half an hour, and it is difficult to start again. Hpmont inverters are equipped with motor speed tracking function, which enables the ventilators to start without the condition of speed decreasing to zero.

Ventilators, Yunnan, China- 355 kw

Steel rolling machine, Myanmar - 220 kw

Oil Pump, Singapore - 450 kw

Waste heat generation, Guizhou, China - 13 units 37~450 kw

Tempering furnace ventilator, Foshan, China - 132kw / 355kw

In the future, Hpmont will continue to delve into promoting technology innovation and providing more comprehensive industrial automation solutions. We envision that our solutions could be worldwide applied just as dandelion seeds spreads everywhere.