Hpmont warp knitting machine system solution helps you double efficiency!

In the ancient time, textile relied more on manual labor, which was not efficient and delicate. As modern textile industry develops nowadays, more specialized machines are utilized for spinning, weaving, dyeing, finishing, etc. And people’s pursuit of skillful workers has shifted to precise control of machine.

The annually increasing application of high speed warp knitting machine

Compared with the traditional chain-type warp knitting machine, the high-speed warp knitting machine is electrified, realizing higher weaving speed and production efficiency. In addition, it takes less time to replace the knitting pattern because of its simple mechanical structure, which greatly reduces the production cost.

Warp knitting machines are often used in the production of mesh fabrics and fleece fabrics such as swimsuits, sportswear, towels, mosquito nets, fishing nets, medical bandages, socks, etc.

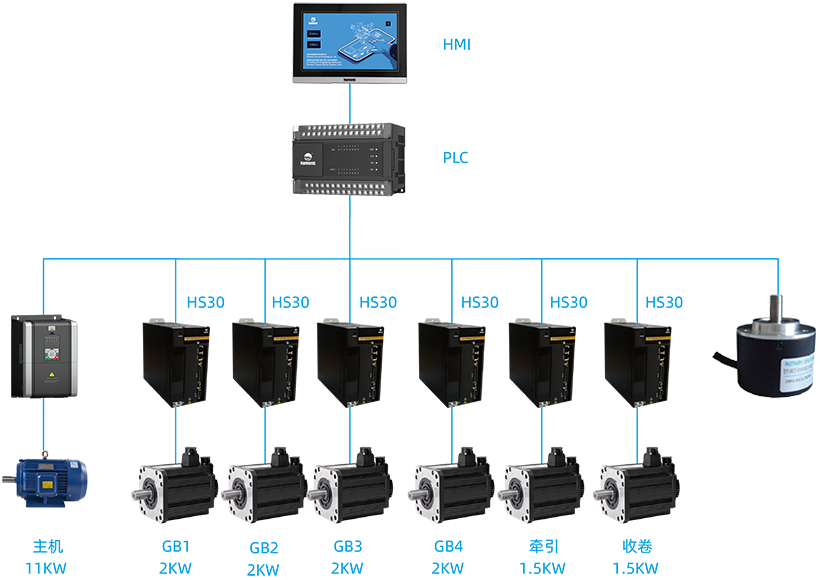

Hpmont high-speed warp knitting machine system solution

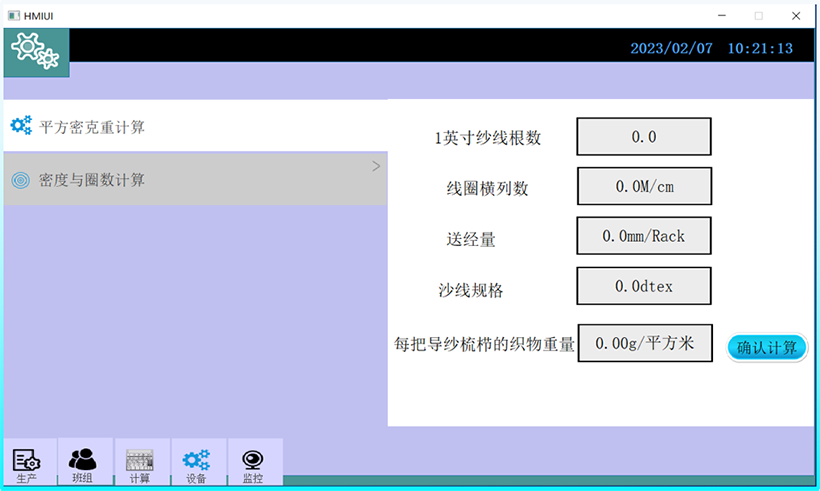

The solution fully takes advantage of HC10's excellent servo positioning function, abundant internal data resources and seamless communication of HS30 servo drives.

System features:

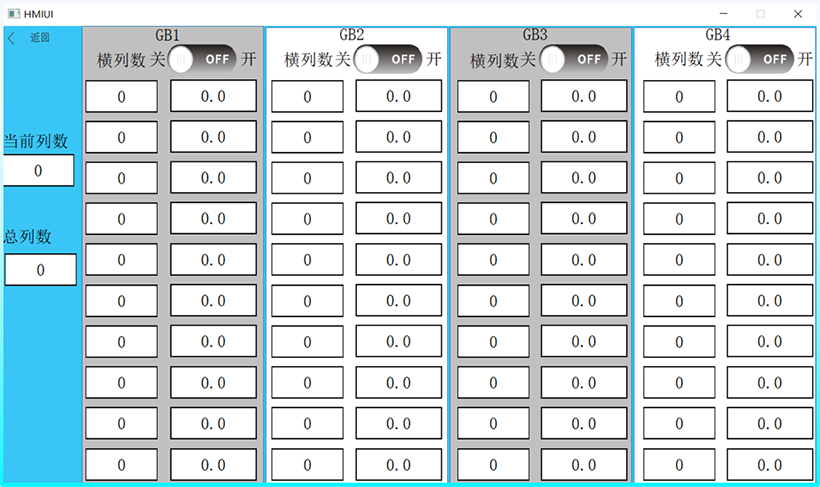

support EBA and EBC, two ways of feeding fabric material, meeting a variety of knitting needs;

system operation and monitoring interface is close to Karl Meyer (Germany)

EBC controlling center disk position (1-48) can be flexibly set

Three-shuttle speed up to 2300

The needle is at the low level during shutdown to ensure that it is not damaged after stopping

Servo and PLC adopts DC power supply, fast response

Application case